Empire's research and development (R&D) is an intricate part of our daily operations. R&D actively supports customer service and focuses on finding solutions and solving problems that support our customers' end-use while creating a repeatable manufacturing process. R&D works in collaboration with our art department, ink department, and production to establish improved processes and enhance our products, services, and technologies.

If you are unsure of how to proceed on a project and require assistance, contact us.

Product Performance Testing

Using modern diagnostic equipment, R&D's product performance testing capabilities provide customers' reassurance that Empire's products will meet or exceed their label and overlay performance expectations.

Chemical Resistance

Used to determine the effect of a chemical on the permanency and legibility of substrates and inks that make up a label. Method and duration of chemical exposure is based on customer specification of potential exposure during normal use of product.

Peel Adhesion

Used to determine the force required to separate a pressure-sensitive material from a specific application surface at an angle of 180º.

Accelerated UV Exposure Testing

Used to determine the effect of exposure of UV light contained in sunlight on substrates and inks used in the construction of the label. Acceleration of exposure is achieved through the use of an air-cooled xenon arc chamber. The chamber provides light at a similar spectrum as sunlight but with exposure significantly higher.

The Blue Wool Scale

The Blue Wool Scale measures and calibrates the permanence of coloring dyes. Traditionally, this test was developed for the textiles industry, but it has now been adopted by the printing industry as a measure of "lightfastness" of ink colorants and also within the polymer industry for measurement of pigment and color stability (lightfastness).

Abrasion & Rub

Use to determine the effect of abrasion and rubbing on substrates and inks that comprise a label. Testing is performed with a range of severities and durations.

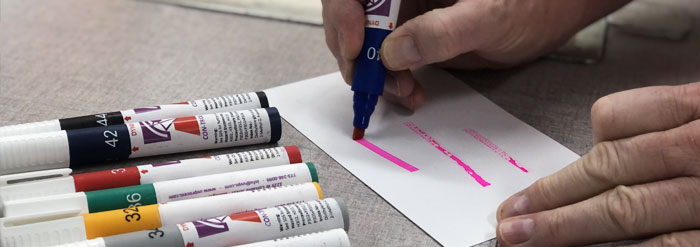

Dyne Testing

Dyne Pen testing is used to measure the surface energy of films and other non-absorptive substrates. Surface energy is directly related to how inks, coatings, or adhesives anchor to a substrate.

Temperature & Humidity Cycling

To determine the effect of temperature and humidity on pressure substrates and inks that comprise a label.

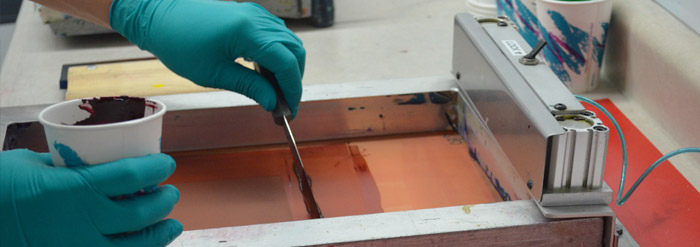

Water Bath

Used to determine the effect of water submersion at specific temperature on substrates and inks used in the construction of the label.